ASME B18.2.1 UNC Sekkantbout Grade 5 Swarte Oksyde Inch Grutte 1/2-13

ASME B18.2.1 UNC Sekkantbout Grade 5 Swarte Oksyde Inch Grutte 1/2-13

Beskriuwing

GAUAntwurd

GAUSitaat

GAUBefalling

KLEAR OM TE FERSTJOEREN

10000+ SKU yn pakhús

Wy sette ús yn foar RTS-items:

70% levere items binnen 5 dagen

80% levere items binnen 7 dagen

90% levere itemsbinnen 10 dagen

Bulkbestellingen, nim dan kontakt op mei klanttsjinst

Nim dan kontakt mei ús op foar mear ynformaasje, lykas it gewicht, de ferpakkingsspesifikaasje, de priislist, ensafuorthinne.

| Dia/d | 1/4 | 16/5 | 3/8 | 16/7 | 1/2 | 5/8 | 3/4 | 7/8 | 1 | 1-1/8 | 1-1/4 | 1-3/8 | 1-1/2 | |

| PP | UNC | 20 | 18 | 16 | 14 | 13 | 11 | 10 | 9 | 8 | 7 | 7 | 6 | 6 |

| UNF | 28 | 24 | 24 | 20 | 20 | 18 | 16 | 14 | 12 | 12 | 12 | 12 | 12 | |

| 8-FN | - | - | - | - | - | - | - | - | - | 8 | 8 | 8 | 8 | |

| ds | maks | 0.26 | 0.324 | 0.388 | 0.452 | 0.515 | 0.642 | 0.768 | 0.895 | 1.022 | 1.149 | 1.277 | 1.404 | 1.531 |

| min | 0.237 | 0.298 | 0.36 | 0.421 | 0.482 | 0.605 | 0.729 | 0.852 | 0.976 | 1.098 | 1.223 | 1.345 | 1.47 | |

| s | maks | 0.438 | 0.5 | 0.562 | 0.625 | 0.75 | 0.938 | 1.125 | 1.312 | 1.5 | 1.688 | 1.875 | 2.062 | 2.25 |

| min | 0.425 | 0.484 | 0.544 | 0.603 | 0.725 | 0.906 | 1.088 | 1.269 | 1.45 | 1.631 | 1.812 | 1.994 | 2.175 | |

| e | maks | 0.505 | 0.577 | 0.65 | 0.722 | 0.866 | 1.083 | 1.299 | 1.516 | 1.732 | 1.949 | 2.165 | 2.382 | 2.598 |

| min | 0.484 | 0.552 | 0.62 | 0.687 | 0.826 | 1.033 | 1.24 | 1.447 | 1.653 | 1.859 | 2.066 | 2.273 | 2.48 | |

| k | maks | 0.188 | 0.235 | 0.268 | 0.316 | 0.364 | 0.444 | 0.524 | 0.604 | 0.7 | 0.78 | 0.876 | 0.94 | 1.036 |

| min | 0.15 | 0.195 | 0.226 | 0.272 | 0.302 | 0.378 | 0.455 | 0.531 | 0.591 | 0.658 | 0.749 | 0.81 | 0.902 | |

| r | maks | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.06 | 0.06 | 0.06 | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 |

| min | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.02 | 0.02 | 0.02 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | |

| b | L≤6 | 0.75 | 0.875 | 1 | 1.125 | 1.25 | 1.5 | 1.75 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 |

| L>6 | 1 | 1.125 | 1.25 | 1.375 | 1.5 | 1.75 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | |

| Dia/d | 1-5/8 | 1-3/4 | 1-7/8 | 2 | 2-1/4 | 2-1/2 | 2-3/4 | 3 | 3-1/4 | 3-1/2 | 3-3/4 | 4 | |

| PP | UNC | - | 5 | - | 4-1/2 | 4-1/2 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| UNF | - | - | - | - | - | - | - | - | - | - | - | - | |

| 8-FN | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | |

| ds | maks | 1.658 | 1.785 | 1.912 | 2.039 | 2.305 | 2.559 | 2.827 | 3.081 | 3.335 | 3.589 | 3.858 | 4.111 |

| min | 1.591 | 1.716 | 1.839 | 1.964 | 2.214 | 2.461 | 2.711 | 2.961 | 3.21 | 3.461 | 3.726 | 3.975 | |

| s | maks | 2.438 | 2.625 | 2.812 | 3 | 3.375 | 3.75 | 4.125 | 4.5 | 4.875 | 5.25 | 5.625 | 6 |

| min | 2.356 | 2.538 | 2.719 | 2.9 | 3.262 | 3.625 | 3.988 | 4.35 | 4.712 | 5.075 | 5.437 | 5.8 | |

| e | maks | 2.815 | 3.031 | 3.248 | 3.464 | 3.897 | 4.33 | 4.763 | 5.196 | 5.629 | 6.062 | 6.495 | 6.928 |

| min | 2.616 | 2.893 | 3.099 | 3.306 | 3.719 | 4.133 | 4.546 | 4.959 | 5.372 | 5.786 | 6.198 | 6.612 | |

| k | maks | 1.116 | 1.196 | 1.276 | 1.388 | 1.548 | 1.708 | 1.869 | 2.06 | 2.251 | 2.38 | 2.572 | 2.764 |

| min | 0.978 | 1.054 | 1.13 | 1.175 | 1.327 | 1.479 | 1.632 | 1.815 | 1.936 | 2.057 | 2.241 | 2.424 | |

| r | maks | 0.09 | 0.12 | 0.12 | 0.12 | 0.19 | 0.19 | 0.19 | 0.19 | 0.19 | 0.19 | 0.19 | 0.19 |

| min | 0.03 | 0.04 | 0.04 | 0.04 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | |

| b | L≤6 | 3.5 | 3.75 | 4 | 4.25 | 4.75 | 5.25 | 5.75 | 6.25 | 6.75 | 7.25 | 7.75 | 8.25 |

| L>6 | 3.75 | 4 | 4.25 | 4.5 | 5 | 5.5 | 6 | 6.5 | 7 | 7.5 | 8 | 8.5 | |

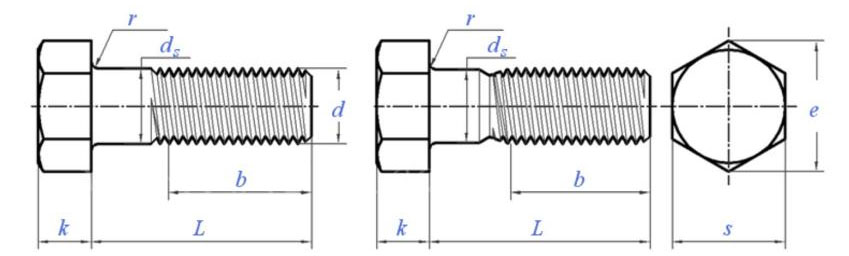

Detailtekening

Wat betsjut "UNC"?

UNC ferwiist nei de grove tried yn 'e ferienige tried fan' e Feriene Steaten UN-searje (opsjonele eksterne triedwoartelradius).

Wat is de oerflakbehanneling fan swarte okside?

Swart okside, in gewoane metoade foar gemyske oerflakbehanneling. Swart okside is in gewoane metoade foar gemyske oerflakbehanneling. It prinsipe is om in oksidefilm op it metalen oerflak te produsearjen om de loft te isolearjen en it doel fan roestprevinsje te berikken. As de easken foar uterlik net heech binne, kin swartmeitsjen brûkt wurde, en it oerflak fan stielen ûnderdielen wurdt swartmakke, wat ek blau neamd wurdt.

De meast brûkte metoaden foar swartoksidebehanneling omfetsje tradisjoneel alkaline ferwaarmingsswartjen en keamertemperatuerswartjen dat letter plakfynt. It swartjenproses by keamertemperatuer is lykwols net heul effektyf foar leechkoalstofstiel. Alkalyske swartjen wurdt ûnderferdield, en d'r is in ferskil tusken ien kear swartjen en twa kear swartjen. De wichtichste komponinten fan swartjenfloeistof binne natriumhydrokside en natriumnitrit. It temperatuerferskil dat nedich is foar swartjen is net grut, en in goed oerflak kin wurde krigen tusken 135-155 °C, mar de tiid dy't nedich is is wat lang.

Ynpakken

Oer ús

* It folgjende diagram identifisearret de ferskate hannelsincoterms. Selektearje dejinge dy't jo foarkar hawwe.

HITE-FERKOOP PRODUKT

Kwaliteit earst, feiligens garandearre